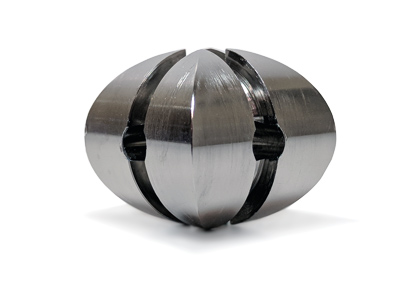

CCTY Bearing Company’s Application Design Team has developed a smoother, stronger bearing for intermittent applications. The square ball is capable of transferring torque through misaligned applications.

Square Ball Universal Joint Advantages

In steering applications over u-joints with needle bearings:

Larger Load Zone

Universal joints with needle bearings are subject to line load fretting on the raceways from continued vibration, reducing the expected service life.

- The SBJ has a larger load zone than the combined line contact area of needle bearings.

- A larger load zone withstands vibrating applications by spreading the same vibrating surface pressure over a larger area.

Low Starting & Operational Torque Resistance

Starting rotational torque of a SBJ is very low, ranging from 0 to 0.025Nm when the operating angle range is 0 to 25 degrees. Since there are only 3 moving parts, starting torque is consistent.

- Needle bearing u-joints can have over 100 parts per assembly. Tolerance stack-up issues with this many components have inconsistent startup torque values from unit to unit.

- Very low and consistent startup torque values of the SBJ provide advantages for autonomous steering applications.

Boot Sealed Design

All moving components are lubricated and maintenance free.

Square Ball Universal Joint Patent Information

An international and US patent for the SBJ has been received:

- US Patent No. 10,443,661

- China P.R. Application No. 20178000404.2